1.SMP08/09 Series

The cutting tool includes key connection and mandrel connection, which can be usedfor slot milling, down milling, parting, face milling and side milling.

The tool body material is made from high-strength steel, with good heat resistance and longertool life.

Itadopts a fully-ground vertical-mounted insert with wide cutting width and wide coverage of the insert tip arc, which can be customized according to your needs.

2.SM09 Series

Mandrel connection

Grooving

Key connection

The cutting width of the tool is 12-26mm, and the diameter of the tool is 80-315mm,which can be customized according to customer’s needs.

The insert adopts a large point inclination angle, double-sided positive inserts with light cutting action, smooth chip removal, then effectively reducing the cutting vibration.

The insert contains 2 left and 2 right cutting edges, and the peripherally ground insert

has good product consistency, achieving machining on plain bottom groove with good flatness.

3.General GeometryLNGX-GM

The insertis equipped with 4 cutting edges and combines the economy of ZCC CT excellent milling grades with versatility for various kinds of materials machining.

The geometry balance the sharpness and the strength of the edge with light cutting and good versatility which is recommended for light and medium cutting parameters.

4.General machininggeometry

LNGX-GM

StandardRE

Different radius can be customized according to customer's needs

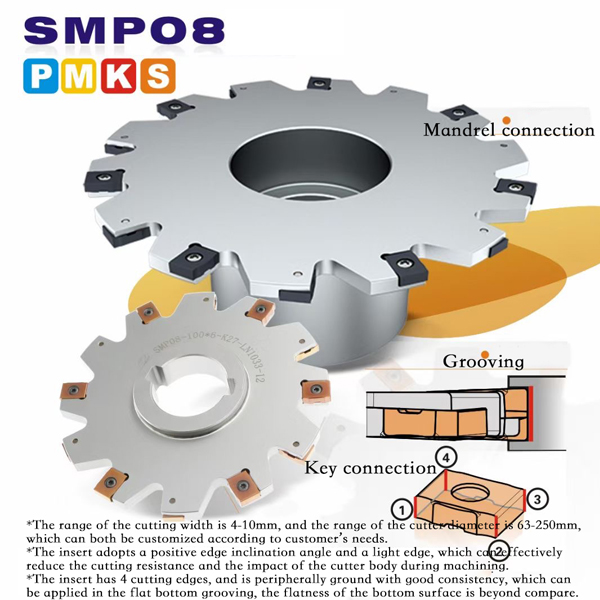

5.SM108series

Mandrel connection

Grooving

Key connection

The range of the cutting width is 4-10mm, and the range of the cutter diameter is63-250mm, which can both be customized according to customer’s needs.

The insert adopts a positive edge inclination angle and a light edge, which can effectively reduce the cutting resistance and the impact of the cutter body during machining.

The insert has 4 cutting edges, and is peripherally ground with good consistency, which can be applied in the flat bottom grooving, the flatness of the bottom surface is beyond compare.

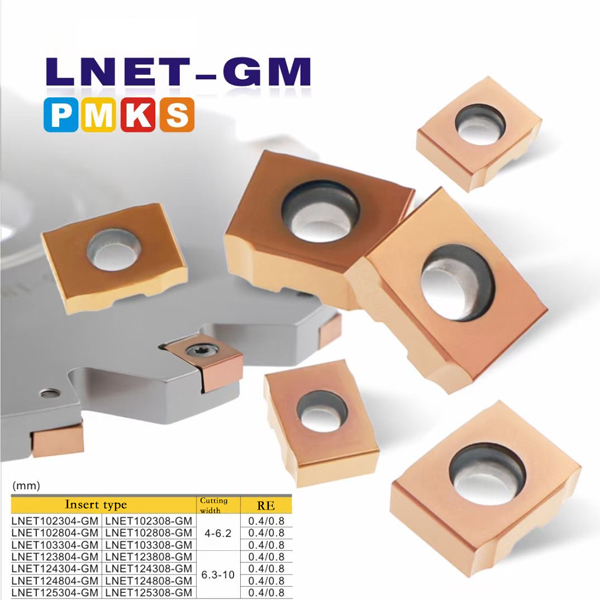

6.LNET-GM

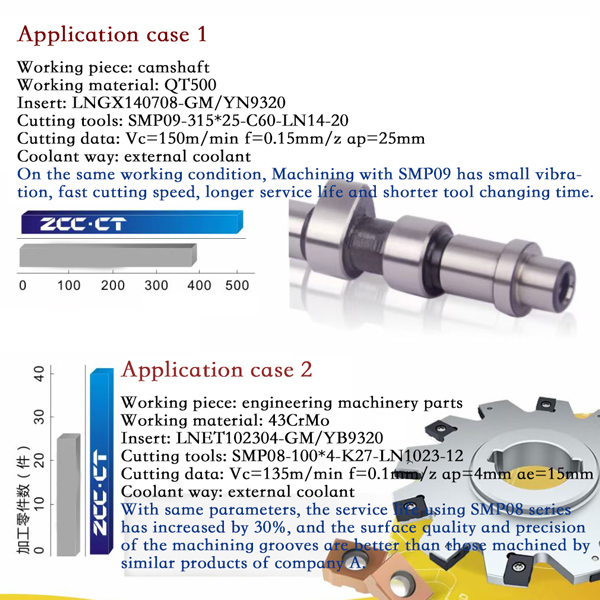

Applicationcase 1

Workingpiece: camshaft

Workingmaterial: QT500

Insert: LNGX140708-GM/YN9320

Cuttingtools: SMP09-315*25-C60-LN14-20

Cuttingdata: Vc=150m/min f=0.15mm/z ap=25mm

Coolantway: external coolant

On the same working condition, machining with SMP09 has small vibration, fast cutting speed,longer service life and shorter tool changing time.

Applicationcase 2

Workingpiece: engineering machinery parts

Workingmaterial: 43CrMo

Insert: LNET102304-GM/YB9320

Cuttingtools: SMP08-100*4-K27-LN1023-12

Cuttingdata: Vc=135m/min f=0.1mm/z ap=4mm ae=15mm

Coolantway: external coolant

With same parameters, the service life using SMP08 series has increased by 30%, and the surface quality and precision of the machining grooves are better than those machined by similar products of company A.

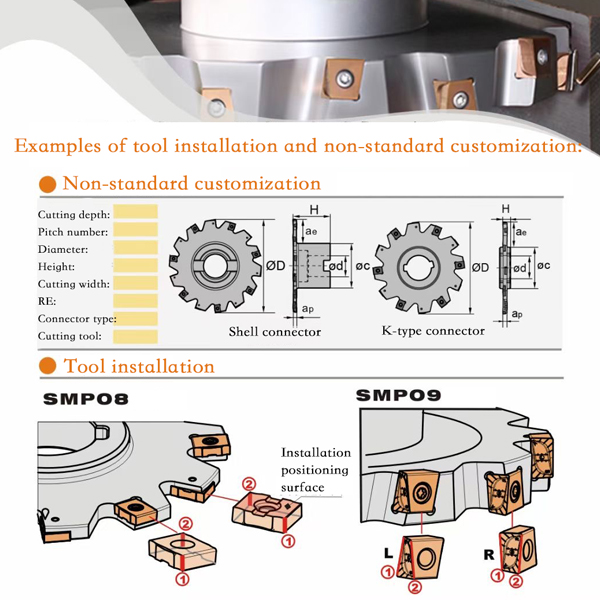

7.Examples of tool installation and non-standard customization